Effluent Treatment Plant (ETP)

Effluent Treatment Plant Design

Effluent Treatment Plant Design

Effluent treatment is a process of removing contaminants from wastewater. The whole treatment contains various physical, biological and chemical processes. Its aim is to release safe water to environment so that it cannot harm the environment.

Benefits of Effluent Treatment Plant

In recent times, all manufacturing companies face strict regulations on waste and its unregulated discharge. Non-Compliance to them can lead to fine and operational interference from pollution control board. In addition to that a wastewater treatment plant provides folowing benefits as well :

- Keeps the company in compliance

- Reduces supply cost by recovering production materials out of the waste stream for reuse

- Eliminates extra water usage during processing

- Reduces hauling and off-site treatment cost

Wastewater treatment plant design is primary process in which untreated waste water is analyzed and based on requirement of uses treated effluent plant is designed. Furthermore, an ETP is to treat non-hazardous industrial waste water while being cost-effective, should require minimal maintenance and manpower. The treatment process should be inclusive of pH change, aerated lagoon, polishing/infiltration ponds and sedimentation/facultative basins etc.

The design of effluent treatment plant is often industry specific reason being the difference in inlet parameters. Characteristics of site, required treated effluent standards, trearmennt method used aer some other parameters which play major role in designing..

ETP Design Parameters

Abve mentioned site characteristics include soils, topology, geology, hydrology, climate and land use. Knowledge of Depth of hardstrata and topography (it’s the way where height and depth of land shown in green and yellow Color in map)can be utilised to design gravity flow and burial of pipes which are of utmost importacnce in plumbing of an ETP plant. Soil thickness, its content, its characteristic, organic, inorganic matter and permeability (capacity of holding water) are to be kept in mind while structural design. Precipitation often plays an important role where infiltration is problem. The role of evapotranspiration becomes imporatant as one of the treatment process uses evaporation.

Apart from above mentioned soil chaaracteristics, physical, chemical and biological characteristic of wastewater need to be kept in mind while deciding methodology. Size of ETP is depends upon its flow Flow of wastewater should be estimated correctly considering all possible reasons otherwise they will affect hydraulic computations, channels and pipes. Physical Characteristic of Wastewater include pH, colour, odour, temperature. suspended solids, grease, oil indicate highly polluted wastewater with very low turbidity. Presence of these matters indicate that need of pre-treatment before releasing to environment. Chemical characteristic of wastewater includes organic, inorganic in solutions and gases. BOD for untreated and treated gives idea about efficiency of Effluent treatment plant. Chemical oxygen demand (COD) measures biodegradable and non-biodegradable organics. Also ratio between BOD and COD tells much more about ETP health. Removal inorganic substances such as chlorine, nitrogen, heavy metals, cyanides phosphorous and sulphur from effluent should also be kept in mind to avoid excessive algae growth caused by nitrogen and phosphorous.

Questionnaire for ETP Plant Design.

- What national or international standards must you comply with?

- Treatment methodology to be used in Effluent Treatment Plant

- What is the volume of effluent ?

- What is its chemical composition ?

- Do you plan to increase production in future?

- Will this increase the amount of effluent to be treated?

- How much can you afford to spend on constructing an ETP?

- How much can you afford to spend on running an ETP?

- How much land do you have available for the ETP?

- What type of plant will best suit your requirements? (The answers that you give to the above questions will help you and the designers to decide this).

- Do you need to hire more staff or train existing staff?

What do we offer?

What do we offer?

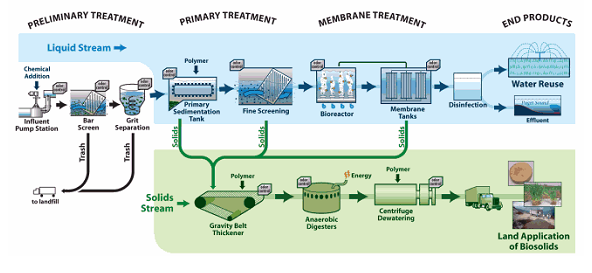

We offer a complete and effective range of Effluent Treatment Plants and solutions to enable recycling of wastewater, thereby reducing the water demand burden. Our comprehensive treatment solution works at various levels and involves various physical, chemical, biological and membrane processes. We Design, Manufacture, Supply, Erection and Commissioning Effluent Treatment Plant (ETP) on Turnkey basis for various types and nature of wastewater, effluents which combine advanced physico-chemical treatment processes with tertiary polishing system for the removal of organic, inorganic, oil and grease, heavy metals & suspended solids.

Our systems include physico-chemical treatment, biological treatment, tertiary treatment and membrane separation process to achieve zero-discharge standards laid by the statutory authority.Our methodology - We analyze the effluent samples for different effluent parameters as per nature and compositions, carry out the treatability studies by using different methods checking techno-commercial Feasibility and then designed treatment schemes, processes accordingly to suit the purpose and need.

Our ETP systems are very compact, tailor made designs, portable required very less foot-print to accommodate, energy efficient. The up-gradation, modification in the existing ETP system is possible to achieve desired limiting standard laid down by the Pollution Control Board (PCB).

The organizational expertise, innovative designs, the performance of the systems, the service provided and maintenance and economical systems have been appreciated by clients.The clientale includes industries like chemicals, drugs, pharmaceutical, refineries, dairy, ready mix plants & textile etc. With the support of vast infrastructure, we are involved in developing highly demanded Effluent Water Treatment Systems. Our offered treatment technologies are compliant to the rigid norms of pollution control board. These treatment plants are developed with robust quality material and prefabricated structures that can be customized as per the clients’ requirement. Further, we are utilizing the sustainable technology of water treatment that is viable in reduction of both organic and inorganic content

Process overview

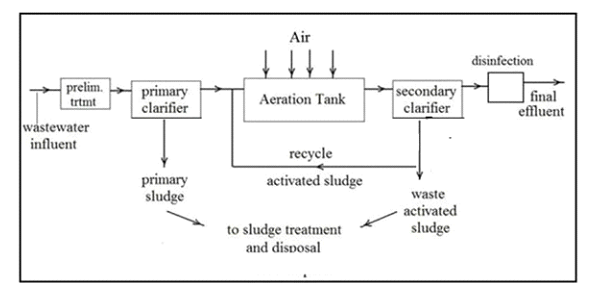

- Primary treatment: Includes Physical treatment for removal of suspended solids.

- Screening/ Grit chamber: To remove floatable matter and sand, grit, stones in raw effluent.

- Oil & grease trap: To remove floatable oil and grease from raw effluent.

- Secondary Treatment: Includes biological treatment for reduction of BOD/COD and solid-liquid separation. Biological treatment can be aerobic or anaerobic depending upon quality of raw effluent. Aerobic- ASP (Activated Sludge Process), MBBR/FAB (Moving Bed Bioreactor/ Fluidized Aerated Bioreactor), SAFF (Submerged Aerated Fixed Film Bioreactor), MBR (Membrane Bioreactor) Anaerobic- UASB (Up-flow anaerobic Sludge Blanket Reactor)

- Tertiary treatment:Sand and Carbon filtration for removal of suspended solids and organic material. Ultra-filtration and Reverse Osmosis are the advanced technologies to be implemented for zero-discharge system.

Features

Easy installation

Easy maintenance

Longer shelf life

We design ETP that finds application in:

- Electroplating and phosphate Industries

- Paper industries

- Steel Mills

- Sugar Mills

- Dyeing industries

- Food & Beverage Industry

- Pharmaceutical & Drug Plants

- Tannery

- Automobiles

- Zero liquid discharge

- Minimal sludge production

- Lower operating cost

Features

Industrial Effluent Treatment Plant is the process of treating waste water that is contaminated by industrial or commercial wastes. Industries produce waste that might highly contaminate the surroundings; to avoid this industrial effluent treatment is required. These effluent treatment plants are used for purifying waste material that is an industrial waste . treatment plants help in solving environmental pollution issues without exposing same to open environment. These effluent treatment plants are known for saving energy and removing pollution effluent with economical operations and also meet stringent pollution control norms These effluent treatment plants can treat effluent coming from different areas of plant.

Features

High performance

Long working life

Robust design

Effluent Treatment Plant Design

We Design, Manufacture, Supply, Erection and Commissioning Effluent Treatment Plant (ETP) on turnkey basis for various types and natures of wastewaters, effluents which combines advanced physico-chemical treatment processes with tertiary polishing system for the removal of organic, inorganic, oil and grease, heavy metals & suspended solids.

Our methodology - We analyze the effluent samples for different effluent parameters as per nature and compositions, carry out the treatability studies by using different methods checking techno-commercial f easibility and then designed treatment schemes, processes accordingly to suit the purpose and need.

Our ETP systems are very compact, tailor made designs, portable required very less foot-print to accommodate, energy efficient. The up-gradation, modification in the existing ETP system is possible to achieve desired limiting standard laid down by the Pollution Control Board (PCB).

Benefits of Effluent Treatment Plant

All manufacturing companies face strict regulations on waste and discharge. Non-Compliance can lead to fine and operations interference from pollution control board.

Wastewater treatment plant can be beneficial for :

- Stay in compliance

- Eliminate fine

- Eliminate extra water usage during processing by recycling the treated water

- Reduce hauling and off-site treatment cost

Wastewater treatment plant design is primary process in which untreated waste water is analyzed and based on requirement of uses of treated effluent plant is designed. Also design of effluent treatment plan is highly site and industry specific.

Design of effluent treatment plant is to treat non-hazardous industrial waste water and should focus on cost-effective, minimal maintenance and requires minimal manpower etc.

Also these plants should include processes such as pH change, aerated lagoon, polishing/infiltration ponds and sedimentation/facultative basins etc.

Design of Effluent treatment Plant

As specified above design of effluent treatment plant is highly depends on industry and site. Major points taken into consideration while designing effluent treatment plants are characteristics of site and wastewater. Untreated effluent standards and treated effluent standards are also taken into consideration in process of wastewater treatment plant design.

Also now coming to selection treatment process, it involves consideration for other multiple factors, Such as treatment efficiency, cost and reliability.

Read More What is Effluent treatment Plant?

Characteristic of Site in ETP Design

Characteristic of site like soils, topology, geology, hydrology, climate and land use are taken into consideration while designing ETP. Knowledge of Depth of rock layer and topography (it’s the way where height and depth of land shown in green and yellow Color in map) also helps in designing of ETP for using gravity flow and burial of pipes which are most necessary.

Soil thickness, its content, its characteristic, organic, inorganic matter and permeability (capacity of holding water) are also taken into consideration in ETP design Process. ETP plant may affect land used in ETP construction.

Also precipitation is considered when infiltration is problem and evapotranspiration used when wastewater treatment includes process of evaporation.

Characteristic of Wastewater in ETP Design

Characteristic of wastewater must be taken into consideration in terms of physical, chemical and biological characteristic. Size of effluent treatment plant i.e. ETP is depends upon its flow (measured in m3 / day. Flow of wastewater should be estimated correctly considering all possible reasons otherwise they will affect hydraulic computations, channels and pipes. Also if there is need to construct equalization pond due to temporary large flow (eg rainfall etc.) to maintain constant flow downstream treatment process. Equalization ponds also helps to reduce toxicity of wastewater.

Physical Characteristic of Wastewater include PH, Colour, odour, temperature. Suspended solids, grease, oil indicate highly polluted wastewater with very low turbidity. Presence of these matters indicate that need of pre-treatment before releasing to environment. Temperature is also major factor because higher the temperature higher the reaction rate.

Chemical characteristic of wastewater includes organic, inorganic in solutions and gases. Biological Oxygen demand (BOD) is indicator of amount of biological substances (proteins, fats, etc.) present in effluent. Comparison of BOD for untreated and treated gives idea about efficiency of Effluent treatment plant.

Chemical oxygen demand (COD) measures biodegradable and non-biodegradable organics. Also ratio between BOD and COD tells much more about ETP health.

Removal inorganic substances such as chlorine, nitrogen, heavy metals, cyanides phosphorous and sulphur from effluent is also important because Nitrogen and phosphorus prone to excessive algae growth and harmful heavy metals increase toxicity.

Due to microbiological actions in wastewater treatment methods produces various gases. The type of gases indicate whether aerobic or anaerobic degradation is taking place.

Questionnaire for ETP Plant Design

Below are some of the questions which will help you to understand type of effluent treatment plant is required.

- What national or international standards must you comply with?

- What volume of effluent do you have?

- What chemicals does it contain?At what concentrations?

- Do you plan to increase production in future?

- Will this increase the amount of effluent to be treated?

- How much can you afford to spend on constructing an ETP?

- How much area you can allot for ETP?

The answers that you give to the above questions will help you and the designers to decide this.